Aug. 14, 2019

Eric Stann, stanne@missouri.edu

When food is recalled due to contamination from bacteria such as salmonella, one may wonder how a tainted product ended up on store shelves. New technology being developed at the University of Missouri could give retailers and regulators an earlier warning on dangers in food, improving public health and giving consumers peace of mind.

The biosensor provides a rapid way for producers to know if this invisible danger is present in both raw and ready-to-eat food before it reaches the store. Annually, more than 48 million people get sick from foodborne illnesses in America, such as salmonella, according to the Centers for Disease Control and Prevention.

A biosensor provides a rapid way for producers to know if this invisible danger is present in both raw and ready-to-eat food before it reaches the store.

“Current tests used to determine positive cases of salmonella — for instance culturing samples and extracting DNA to detect pathogens — are accurate but may take anywhere from one to five days to produce results,” said Mahmoud Almasri, associate professor of electrical engineering and computer science at the MU College of Engineering. “With this new device, we can produce results in just a few hours.”

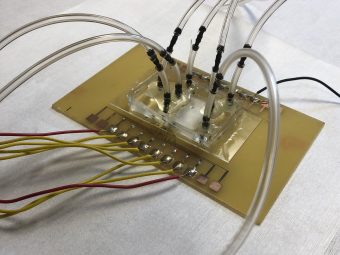

In this study, researchers focused on poultry products, such as chicken and turkey. The biosensor uses a specific fluid that is mixed with the food to detect the presence of bacteria, such as salmonella, along a food production line in both raw and ready-to-eat food. That way, producers can know within a few hours — typically the length of a worker’s shift — if their products are safe to send out for sale to consumers. The researchers believe their device will enhance a food production plant’s operational efficiency and decrease cost.

“Raw and processed food could potentially contain various levels of bacteria,” said Shuping Zhang, professor and director of the Veterinary Medical Diagnostic Laboratory at the MU College of Veterinary Medicine. “Our device will help control and verify that food products are safe for consumers to eat and hopefully decrease the amount of food recalls that happen.”

Researchers said the next step would be testing the biosensor in a commercial setting. Almasri said he believes people in the food processing industry would welcome this device to help make food safer.

The study, “A microfluidic based biosensor for rapid detection of Salmonella in food products,” was published in PLOS ONE, one of the world’s leading peer-reviewed journals focused on science and medicine. Other authors include Ibrahem Jasim, Zhenyu Shen, Lu Zhao at MU; and Majed Dweik at Lincoln University. Funding was provided by a partnership between MU, the Coulter Foundation and the U.S. Department of Agriculture. The content is solely the responsibility of the authors and does not necessarily represent the official views of the funding agencies.

This study details the latest findings for this interdisciplinary team of researchers who have developed multiple biosensors and published results of their previous findings in Scientific Reports, Biosensors and Bioelectronics and Electrophoresis.

Editor’s Note: For more on the story, please see: MU Engineer developing sensor to improve bacteria detection in poultry